There are several urushi lacquer types and each of them is dedicated to a different use.

The Urushi lacquer is part of all the steps of the decorative production, from the preparation of the grounds to the final coatings.

In addition to this the first major distinction in the case of urushi types is between raw and refined lacquer.

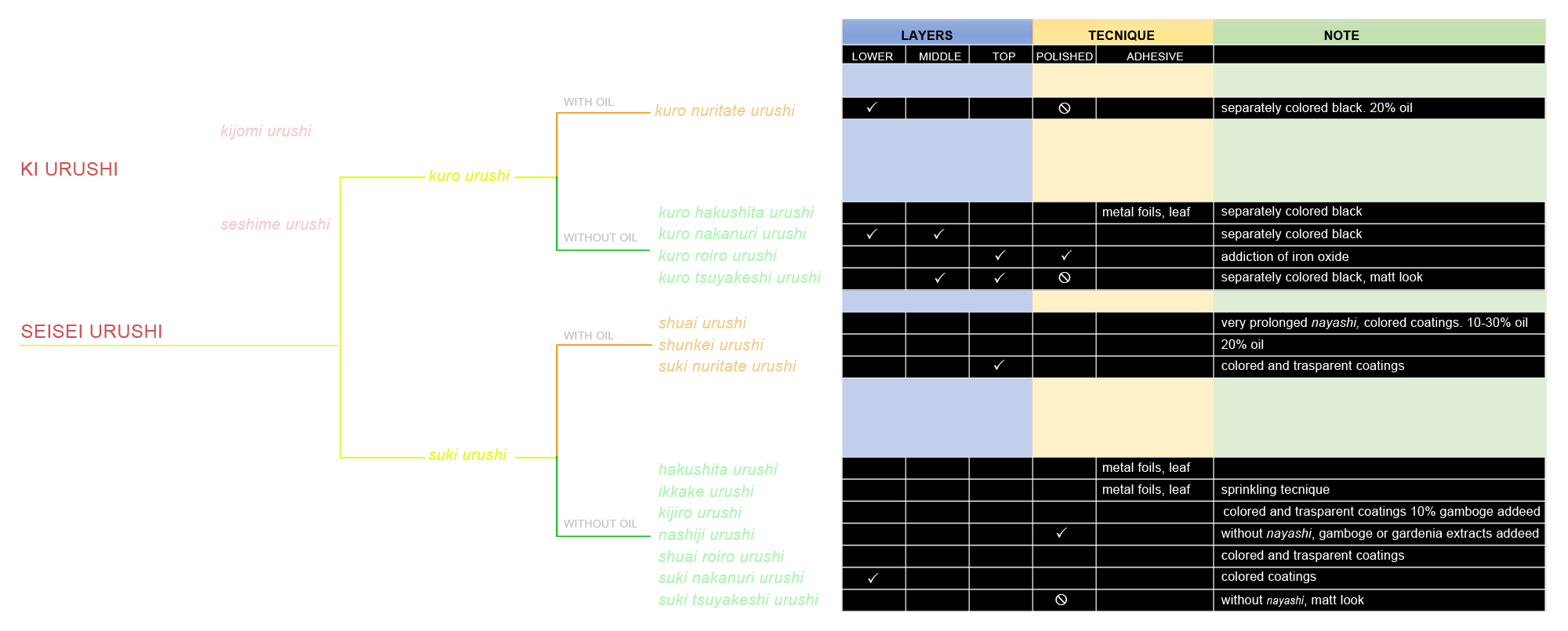

Refined process of urushi

There are two important steps in the refined process of the lacquer. They are generally done together.

The first, called kurome, is a dehydratation process. In this process is very important that the water content in the raw lacquer must reduced very slowly.

The second, called nayashi, is a process of homogenization. Oils (sesame, linseed, princess tree and rapeseed oil), resins (pine, gamboge) or coloring agents (pigments, iron filings) are added to the raw lacquer during the homogenization stage, depending on the viscosity to be obtained and the use of the finished lacquer.

Black urushi lacquer

Iron hydroxide (mixture of iron sulphate and caustic soda in a 10:3 ratio) reacts very rapidly with urushi and should be addeed at the end of the dehydratation process. It is mixed with water and then the precipitate is washed and filtered several times before it can be used for coloring.

Lacquer types diagram

A simplified diagram of the distinctions of different types of urushi lacquer:

References

Heckman Gunther, “Urushi no Waza, Japanese Lacquer Technology“, Nihon Art Publishers, Ellwangen, 2002. ISBN – 3980575527